Constant innovations have made Fiber Laser systems the logical choice for every fabricator. The advantages are obvious.

The question then is…which one?

Let’s talk. We can help you decide.Let us help you

Find the Right Machine

Eagle iNspire fiber lasers have IPG laser sources ranging from 1 to 30kW, cutting speeds of up to 350 M/min, and an acceleration of nearly 6G. These powerful machines are ideal for demanding production applications.

Discover

eVision machines offer positioning speeds of 180 M/min, 3G acceleration and IPG laser source power ranging from 1-30kW. They provide an excellent solution for typical production runs..

Discover

Eagle eSmart lasers are an economical choice with many features. They have cutting speeds of 100 m/min and acceleration of 2G with IPG laser source power of up to 10kW.

Discover

The HF Expert Laser Cutting Machine (G3015) is a professional-grade powerhouse engineered for ultra-high power (up to 60kW. It's compact, integrated architecture optimizes space and maintenance efficiency, delivering unmatched performance for demanding manufacturing environments.

Discover

These dual-drive gantry laser cutters combine precision mechanics with ytterbium-based fiber laser technology, achieving 35% electro-optical efficiency for low-cost 24/7 operation. The optimized drive structure ensures stability through balanced inertia-torque ratio, while modular semiconductor design enhances adaptability for continuous industrial production.

Discover

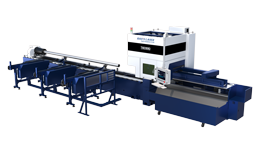

The PD Series Laser Tube Cutting Machine are engineered for precision CNC metal pipe processing, supporting efficient cutting of square, round, oval, and specialty tubes (mild steel, stainless steel, aluminum alloy, etc.). They boost productivity with fast cycle times and exceptional stability.

Discover

The TD series by Han's Laser Smart Equipment Group are high-powered CNC laser tube cutting machines equipped with IPG/Han's laser sources and high-precision transmission components (rack-and-pinion, linear guides). They cut carbon steel, stainless steel, aluminum alloy tubes (round, square, oval) with high speed, accuracy, and cost efficiency.

Discover

AlmaCam has been developing CAM software since 1975 and is a leader in the supply of 2D and 3D machine programming solutions suitable for all sheet metal and pipe-cutting technologies.

Learn More

Improve press brake productivity and increase precision with Robotically Integrated Bending Solutions (RIBS). You can automate virtually any bending process. Complete offline programming software provides fast and predictable results in minutes.

Learn More

© 2023 Paramount Machinery Inc. All rights reserved.